A lot of things must work well together to bring a computer numerical control (CNC) design to life. And with all the options available, it can be hard to figure out the best CAD software and CAM software to start with. But before you begin, it’s essential to know that there are three software steps involved in CNC design to production.

The first step is the creation of a vector file. This mathematically precise file uses formulas to establish grid points. This can be done within CAD software to create designs that will act as the blueprint for your models.

The second step utilizes CAM software to define and interpret part geometry from the CAD file to produce a G-code. This code will then be used to determine the manufacturing parameters of the design on the CNC machine.

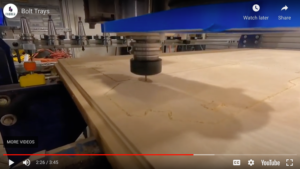

The third step consists of uploading the G-code created by the CAM software to the CNC machine. This code is used as a set of 3D “instructions” to control length, width, and depth along the x, y, and z-axis and guide depth, tool speed, and traverse speed at the CNC Machine.

What is CAD Software?

Computer-Aided Design (CAD) software allows designers to create precise 3D drawings in preparation for production on CNC equipment. This may include adding points, curves, lines, voids, shapes, and other aspects of the part to be produced.

CAD designs for parts are like architectural drawings for a building. However, CAD software renders the drawing virtually in 3D. Parts can be reviewed at any angle or scale, allowing designers to zoom inside and outside of the piece. In this way, flaws, improvements, and other actions can be addressed proactively to optimize the part and reduce required iterations.

What is CAM software?

Computer-Aided Manufacturing (CAM) software is the second step in the CNC process. Here, the geometrical aspects of the CAD file are used to encode production parameters for use on a CNC machine.

The instructions that drive speed, traverse, depth, and axis movement act like the Bill of Materials (BOM) used to create physical objects. Except with CAM software, no physical drawing is needed. The software converts the instructions for these parameters into G-code for use in the CNC equipment.

What is CAD/CAM Software?

Now that you know what CAD and CAM software are, you should also know that they can be combined in a single software package called CAD/CAM. This software combines CAD features with CAM to offer a one-stop solution to produce CNC-ready G-code files.

There are three types of CAD/CAM software, and the one chosen will depend upon the kind of solution sought by the designer. The three types are:

- Free CAD/CAM Software – Free software is best used by enthusiasts and hobbyists creating their design for their use or perhaps for proof of concept for a future project.

Pros

- Cost: Because free is free.

- Simplicity: These programs often contain the features most needed for basic users without a big learning curve.

Cons

- Bugs: A lot of free software can be prone to glitches.

- Security: Care should be taken to ensure it is from a reputable and safe supplier.

- Support: Free software often has little or no support, depending on the supplier.

- Beginner CAD/CAM Software – Beginner software is the next step in CAD/CAM use. For those needing more features than offered by free, but perhaps not the entire suite of features, beginner software has pros and cons as well.

Pros

- Features: More feature-rich.

- Proficiency: Allows incremental improvement of skills leading to pro use (ease of learning/use).

- Cost: This is usually offered in tiered pricing that allows users access to what they need at an affordable price.

Cons

- Quality: Beginner users may find they hit the ceiling on design quality as their skillset grows or as their use case dictates, leaving them just shy of pro-quality.

- Limited Access: Many beginner or tiered programs limit the number of designs per week or month and may restrict access to tools and support needed for improvement.

- Pro CAD/CAM Software – Pro software is enterprise-level software that focuses on offering the complete feature set and highest design quality possible.

Pros

- Unlimited Access: Pro software doesn’t limit the user, meaning they can design as many files as needed for production.

- Features: Pro software unlocks all feature sets, meaning more precise, accurate, and high-quality design.

- Interoperability: Pro software is often compatible with file types and software used by customers making file exchange seamless.

- ROI: For businesses, pro software is measured as an ROI instead of a “cost.”

Cons

- Ease of Learning – Pro software requires pro skill sets. This means hiring or teaching staff to use them.

- Cost: Pro software is more expensive for pro users such as freelancers and high-skilled individuals outside commercial users.

Conclusion

CAD/CAM software can take your designs to the next level and ensure that files sent to the CNC equipment will produce the part as designed. Now that you know everything about CAD and CAM software and how it can help you at any level, you can choose the best version for your needs.